Never in the history of coinage has technology developed at a greater speed than during the past half century. Ever since collecting commemorative coins became a national sport during the silver boom in the 1970s, mints around the world have been competing to produce attractive coins to retain as many customers as possible. After all, coins made with state-of-the-art technologies certainly are a good deal – for both parties. Customers expect the first coins minted with a new technology to rise in value, and sometimes they actually do, and mints are happy about sold-out issues.

However, problems arise when marketing divisions claim that their coins were produced with a brand new technology for the sake of making more profit even though the method isn’t that new but a minor adaptation of something that has already been done before.

This article gives you an overview of the most important techniques used today.

1. Special Minting Techniques

An example of frosting: this Canadian 10 dollar coin of 2020 depicting the famous Changing of the Guard ceremony in front of the parliament in Ottawa (photo: CoCo CA-2020-0108 / Royal Canadian Mint).

1.1 Frosting

One of the oldest techniques is so old and widely used that we no longer notice that it actually is a special technique. But it truly is since the various levels of frosting that are used today to make a relief stand out from a field struck in FDC quality are so refined that applying them in the best way possible is an art in itself.

Whereas minting engineers used to slightly roughen the dies by hand to achieve this effect, now this step is part of the production process or post-production treatment of the dies. This means that the frosting quality will be the same for the entire issue no matter how many coins are produced. And we have to remember that the mintage numbers for commemorative coins of some mints – such as German mints and the US Mint – are so high that these institutions need numerous dies.

A clever way to use high relief technology: on this 25 dollar coin issued on behalf of Palau, CIT depicts the topography of the mountain Carstensz Pyramid in Indonesia (photo: CIT Coin Invest Trust AG).

1.2 High Relief

Spectacular and impressive: high relief coins have virtually revolutionised the field of commemorative issues in recent years – at least regarding low-mintage coins that not have to be produced with a toggle lever press due to high mintage numbers. With such a press, one can only produce coins with a very low relief. Thanks to new technologies, now it is once again possible to create high-relief issues, it has already been while since such reliefs were made, we’re talking about 19th century medal production.

To achieve this technically, there are three options. First, regarding several metals it’s possible to create blanks in a special procedure that have improved flow qualities due to an altered crystal structure, this means that less pressure is needed to create high reliefs.

Other blanks already have elevations at places where more metal is to be used later prior to the minting process. Whenever we see several raised elements that aren’t at the centre of a commemorative coin, such pre-shaped blanks were used in the minting process of that coin.

Last but not least, the production of coins by means of an oil hydraulic press has been optimised in such a way that the pressure can be applied at the exact speed and with just the right amount of force necessary to let the material flow in an ideal way. Combine this with multiple striking, you can achieve almost any relief you want as long as you have enough time to strike the coin.

The results are impressive. The aesthetic quality achieved by means of high relief minting can easily compete with what the predecessors of our coin designers produced in the Renaissance and Baroque periods.

Latvia issued this beautiful 5 euro coin in the shape of a lime leaf in 2020 (photo: CoCo LV-2020-0003 / Latvijas Banka).

1.3 Special Shapes

Special shape coins produced today range from simple square klippes to minted miniature sculptures. The general principle is to produce minting equipment in various shapes. The options range from relatively simple issues made with an upper and a lower die as well as a collar, which isn’t round but square, to state-of-the-art minting equipment consisting of several parts which surround special blanks from all sides. At this point we only need to recall the products made by the Polish Mint, which created numerous, almost incredible miniature sculptures ranging from a globe to a fish.

Creating such elaborate dies in an amount of time that is reasonable from the financial point of view was made possible by the digitalisation of die engraving. The three-dimensional coin design is now created on the computer. The machine calculates how the dies can be created in the best way possible in order to produce such a numismatic mini-sculpture.

A particular type of these special shape coins that is very common now are curved issues, the Royal Australian Mint used them to create a magnificent starry sky and the US Mint created curved commemorative coins dedicated to ball games.

This 2020 British James Bond coin of 200 pounds shows the names of the movies of this series as micro inscription on the logo on the reverse (photo: CoCo GB-2020-0050 / Royal Mint).

1.4 Micro inscriptions

An element of commemorative coins that has made its way onto circulation coins is microprinting, which can also be found on banknotes. As the name suggests, microprinting refers to particularly small letters. However, the term also covers other tiny depictions or logos that were produced in the same way.

That microprinting is used to such a great extent today is due to the fact that coin designs are no longer produced by hand using a plaster model but on the computer screen. Since you can enlarge the image on the screen as much as you like, it is possible to implement ever smaller structures.

Micro inscriptions are engraved into the die by means of a laser. Theoretically, there is no limit to the fineness of the lines that such a laser can produce. Even nanostructures are possible. In practice, the limit is reached when the fine structures of the die can no longer be transferred to the coin in the minting process. The basic rule is: the slower the striking process, the more detailed the micro inscription can be.

It is proof for the high quality of today’s minting presses that, in some countries, micro inscriptions are even used on mass-produced circulation coins.

1.5 Latent Images

By now, same is true for latent images, which are used as security features today. Artists and engineers were inspired to develop this technique thanks to latent images that have been widely used since the Baroque period. These images work because two or three depictions were painted on different sides of slats, which are arranged in such a way that the observer sees a different image depending on his angle of view.

The same principle was applied to coin production: latent images with two depictions are made of tiny, two-sided structures that show different images on both sides, which means that the image changes depending on how we move the coin in the light.

However, the development didn’t stop at two latent images: the Spanish mint, which specialised in the production of latent images, already issued a quadruple latent image on which one of four different images can be seen depending on the angle of incidence of light.

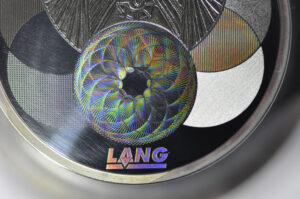

1.6 Iridescent Colours

If you want a surface to show iridescent colours on parts of the coin or the entire issue, even more attention to detail is required to produce the dies. For such coins, the laser has to create nano structures.

The Royal Canadian Mint released a further development in the experimental stage when they demonstrated how a coin can be coloured without applying actual colour. Just like in case of butterfly wings, the colour is created by sort of an optical illusion. Nanoparticles refract the light into a variety of colours.

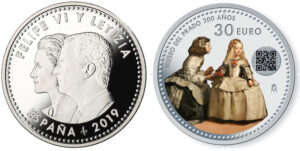

The QR Code of this Spanish coin of 2019 directs you to a website of the Spanish mint with additional information about the coin and the motif (photo: CoCo ES-2019-0001 / Real Casa de la Moneda Fábrica Nacional de Moneda y Timbre).

1.7 QR Codes

Another concept in this area is the idea of minting a detailed QR Code on coins. However, this extension of a real coin into the virtual world of the internet has not been used often until now.

2. Materials

Most Europeans see bimetallic coins every day in the form of euro coins. This is a 2020 French 2 euro coin commemorating General de Gaulle (photo: CoCo FR-2020-0053 / Monnaie de Paris).

2.1 Bimetallic Coins

Bimetallic coins have become such an integral part of our everyday life that we no longer marvel at this miracle of technology. Since the introduction of the euro, we have 1 and 2 euro pieces consisting of a ring and a core made of two different materials. The secret of why ring and centre piece hold together lies in the fact that both parts are deformed during the minting process. When the coin is struck, ring and centre get a little bit larger and the resulting tension makes sure the centre stays in the ring.

Therefore, specimens like “mint error coins” offered on the website of a well-known online auction house shortly after the introduction of the euro are technically impossible: a centre featuring the design of the coin’s reverse inside a ring with the image of the coin’s obverse. (Or the centre of a coin of state a with the ring of a coin of state b.)

According to numismatic portals, the solution to this mystery is mum’s freezer. Due to the low temperature, the metal shrunk enough to loosen the tension between ring and centre piece. The two parts could be separated and were put together upside down. When heated, the metal expanded again and created the tension that was necessary to hold ring and core piece together.

A red bronze outer ring, a cupronickel inner core and a polymer ring between the two: “On land” is the second piece of the German “Air Moves” series and an issue made of three materials. (Photo: CoCo DE-2020-0015 / BVA, Hans-Joachim Wuthenow).

2.2 Trimaterial Coins

Germany made headlines around the world when it issued the circulation commemorative coin “Planet Earth”. However, someone else had already succeeded earlier in producing commemorative issues with a polymer ring. The Zurich coin shop Dietrich sold “Trauereuros” (Euros of Sorrow) in 2010 when Greece fell into the debt trap. These coins had a black polymer ring separating centre piece and ring.

The polymer used for German commemorative circulation coins is significantly enhanced, it can be minted and a variety of colour particles can be added. It can be used to achieve several colour effects that we usually only see on banknotes, for example that the motif of a banknote only appears under red light or ultraviolet light.

Some bullion coins such as the famous Vienna Philharmonic are now available in platinum versions. CoCo AT-2020-0011 / Münze Österreich).

2.3 Special Materials Such as Niobium, Tantalum and Titanium

Actually, one might say, it wouldn’t be so hard to create coins made of other metals if there wasn’t the problem of different crystal structures. That’s why some of these materials are brittle and it’s difficult to mint coins from them. Therefore, striking coins sometimes becomes so cost-intensive that it isn’t worth it. If you wonder why there are so few platinum bullion coins compared to gold and silver issues, this is one of the reasons. Although it is technically possible to mint them, they require much more effort than coins made of common metals.

3. Surface Treatment After the Striking

3.1 Colour Application

When Germany issued its first colour commemorative coin in 2018, the technology used for it was already an old hat. As early as in 1992, CIT had produced the first colour coin in collaboration with Huguenin. The coin was the first piece in Palau’s Marine Life Protection series. This series featuring

coloured motifs of the underwater world became a best-seller and the longest-running commemorative coin series in the history of numismatics.

This 2012 Canadian 25 cent coin of the Prehistoric Creature series is not only a colour coin, it also glows in the dark showing a different motif thanks to phosphorescent colours (photo: Royal Canadian Mint).

Today, colour application is one of the most frequently used techniques for commemorative coins. Several methods were developed to apply colour depending on how long it should last on the coin. If you want to know more about it: we wrote a detailed article on this subject for our MünzenMarkt issue of January 2018.

Of course, you can play with colour. Thus, coins with glow-in-the-dark effect have been created in the last years, i.e. coins that show a different image at daylight than they do in the dark.

By the way, you should pay attention to whether the colour is part of the design concept of the commemorative coin or – and this is common regarding 2 euro coins – whether it was applied later to a coin that had originally be designed without colour. Colour application can be very intriguing and collectible, however, as soon as there is colour on a coin, the piece in question no longer qualifies as legal tender.

Once they were fashionable, today they are hardly used anymore: historical orders such as this Saxe-Ernestine House Order were enamelled to receive their splendid colour. From Künker auction e- 54 (2019), Lot 2234.

3.2 Enamel

Much older than any kind of pad printing is the technique of applying colour by means of enamel, i.e. by means of the same method that has been used for more than two centuries to make medals shine in splendid colours. Colours created by enamel application have a different surface structure and are much more shiny, however, they also require more effort to produce. That’s the reason why this technique has somewhat taken a back seat regarding the commemorative coin production of recent years and is only used on rare occasions.

This beautiful coin by CIT for the island country of Palau has, in addition to many other elements created with special technology, a patinated surface. (Photo: CoCo PW-2021-0005 / CIT Coin Invest AG).

3.3 Patinating

An ancient but still very impressive technique for giving the special something to a coin is patinating, i.e. a chemical treatment of the surface that makes the FDC metal shine in a different shade of grey.

This Canadian 100 dollar coin of 2020 is a beautiful example for selective gold plating (photo: CoCo CA-2020-0055 / Royal Canadian Mint).

3.4 Finishing Techniques With Other Metals – Entirely and Partially Plated Coins

While plating an entire object is rather simple, an incredible effort is required to create an issue with selective gold plating. And the smaller the part to be plated is, the more complicated it gets. The plating has to be attached at the exact spot to achieve an ideal effect.

A 2020 coin of Coin Invest Trust’s Tiffany series with an inserted piece of glass (photo: CoCo PW-2020-0003 / CIT Coin Invest Trust AG).

3.5 Inlays – Applied or Inserted

When the first coin of Coin Invest Trust’s Tiffany series was issued, it was a completely new idea to insert a piece of glass into a coin. Applied Swarovski stones, small capsules with spices, little precious stones, a shimmer of gold, cloverleaves and other things had already been put on coins, but replacing part of the metal with another material was extremely demanding from the technical point of few and it has remained that way to this day.

In 2013 the Royal Canadian Mint released this 20 dollar Superman coin with hologram background (photo: Royal Canadian Mint).

3.6 Holograms

We know holograms mainly from banknote production, but inventive minting engineers use them for coins, too. The secret is producing the coin and the hologram separately. The hologram is glued to the coin, so to speak.

Of course, there are coins combining all these techniques. For example, a patinated high-relief colour coin with inlay and gold plating was created. Such works of art have nothing in common with the mass-produced issues created with a toggle lever press.

In the 19th century, such efforts were only made in the field of medal production. But since medals unfortunately enjoy a bad reputation nowadays, they have been fully replaced by non-circulating legal tender issues – i.e. coins with a face value that cannot circulate in the country where they were issued.

Those who immerse themselves in the world of state-of-the-art minting techniques will appreciate these coins that, although they cannot be used as legal tender, are small works of art reflecting everything that is important to our modern world.

If you are interested in technology topics, check out our minting technology related articles.

And in our Cosmos of Collectibles database you can search for any special technique!